Shearwater Precision provides a range of services to a large section of the Australian manufacturing industry.

Shearwater Precision provides a range of services to a large section of the Australian manufacturing industry.

- Precision engineering

- CAD/CAM modelling and prototyping.

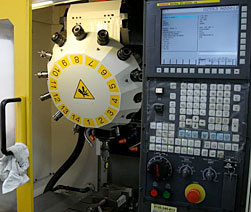

- High speed CNC machinery for fast and accurate Repetition engineering.

- Specialists in the design and manufacture of plastic injection moulds and Press tools up to 6 tonne.

- Breakdown and maintenance services along with reverse engineering of machine parts and processes for a diverse range of clients including the food, construction and printing industries.

- Expert knowledge of special toolsteels and hardening requirements, utilising in-house vacuum furnace to ensure maximum longevity and durability of replacement machine parts and consumables.

- Large capacity milling, grinding and Spark erosion capabilities.

Shearwater Precision History

Shearwater Precision started when two senior staff took over the long established M. F. Dippert Toolroom in 2006.

Since then it has been our priority to maintain the exacting standards and high quality that have existed in the toolroom since 1948.

A combined experience of over 50 years in the industry means we can provide a level of expertise that allows us to meet the demands of your most challenging engineering requirements.

Our plant and equipment includes:

- CAD/CAM for 3D Modeling and Tool Design

- CNC Mills, some with 4 axis, with capacity up to 1750 x 800 x 800 travel and weight up to 6 tonnes

- CNC EDM Spark erosion with 4 axis

- CNC Turning

- Long bed grinding up to 1500mm in length and snow grinding up to 980mm in diameter

- Jig grinding and long hole gun drilling capabilities

For all enquiries please contact:

For all enquiries please contact:

Greg Stankiewicz; or,

Ray Sader

Phone: +61 2 9709 8075

Or email us at info@shearwaterprecision.com.au

Shearwater Precision

16 Exceller Ave

Bankstown NSW 2200